New Products

NEWSLETTER

Please leave to us and we will be in touch within 24hours.

Recommended Products

UPVC foam co extrusion profiles

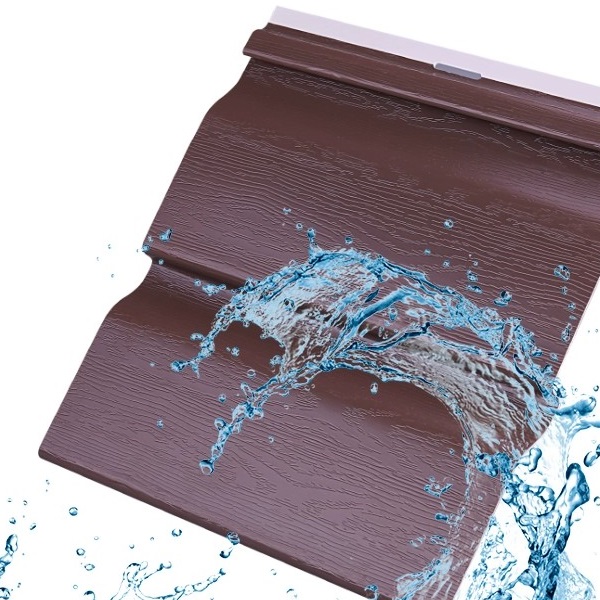

Product Details Product PVC Exterior Wall SidingHanging Board Material PVC-U Size 4m*24cm Thickness 1.2mm Weight 2.65KG Color White,Yellow,Grey….customized. Application Exterior Wall Decoration Installation Fixings Origin China PVC exterior wall hanging board is a kind of plastic profile with pvc as the main body, used for the exterior wall of the building; it plays the role of covering, protection and decoration. 1. Good toughness, nail resistance and external imp...

wall panels pvc board wpc board for wall exteri...

PVC Exterior Wall Siding J Strip PVC Exterior Wall Siding J Strip is used as an edge-closing accessory for hanging boards, usually used around door and window sheaths, around herringbone gables and edge- closing cut surfaces of hanging boards. Product PVC J Strip Material PVC-U Size 4000mm*55mm Thickness 1.2mm Color White,Yellow,Grey….customized. Application Exterior Wall Decoration Installation Fixings Origin China PVC exterior wall hanging board is a kind of plasti...

Wall Panel Insulated Exterior Paints Pvc Siding

100% fresh plastic material 1.Maintenance free 2.Very durable 3.Can be worked as wood 4.Splinter-free / Frost proof 5.Insensitive to fungi and insects 6.Does not exude toxic substance into the environment 7.Wear-resistant/ corrosion resistant/Anti-UV 8.Non-rotting/non-pershable 9.Full range of sizes available,etc 10.Used widely in farm, ranch, road, building, horticulture, gardening ,etc.